The Case for Automation

Automation can help increase the productivity of an existing workforce by as much as 46%.

Learn More

Automation and racking equipment require regular scheduled maintenance to ensure optimal performance and longevity. Our technicians do a full system inspection to check on all components within the system and report on what areas may need upcoming service. We offer maintenance intervals according to the manufacturer recommended schedule and operational needs.

Service including lubrication, calibration, cleaning, and inspection of critical components.

If a faulty component is identified during troubleshooting, it may need to be replaced. Our team will help ensure to get component replacement parts from the equipment manufacturer or authorized suppliers. Our team provides proper component removal and installation, paying special detail to any calibration or alignment requirements.

When automation equipment malfunctions or experiences issues, troubleshooting becomes crucial. Our automation technicians will help find the source of the problem to get your equipment back up and running.

Automation equipment often relies on software systems to operate efficiently. Stay updated with the latest software versions and firmware releases provided by the manufacturer. Follow the recommended procedures for updating the software, which may involve connecting the equipment to a computer or network.

Our technicians will provide a one-time walk-through and check on all components within the system and produce a report on the next components that might need to be addressed soon.

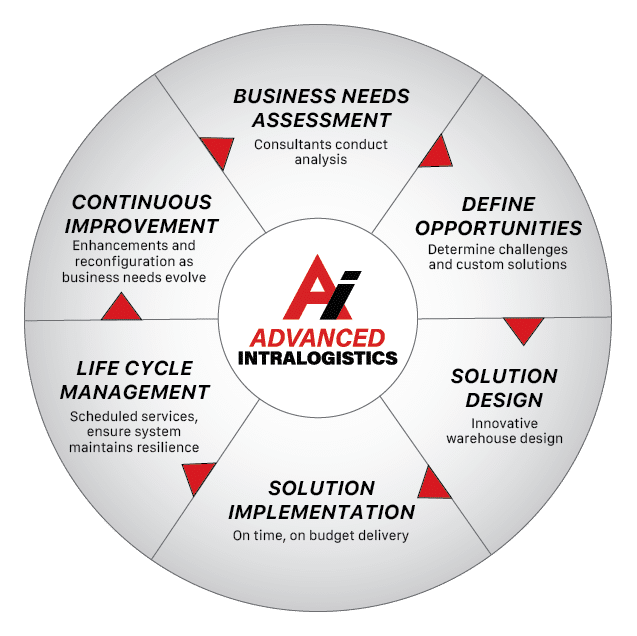

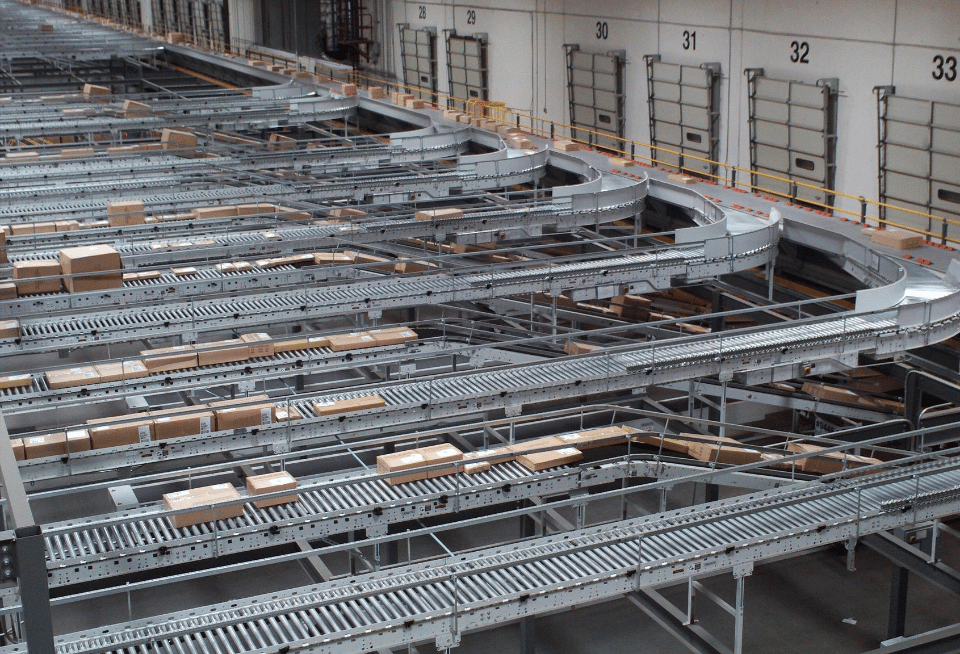

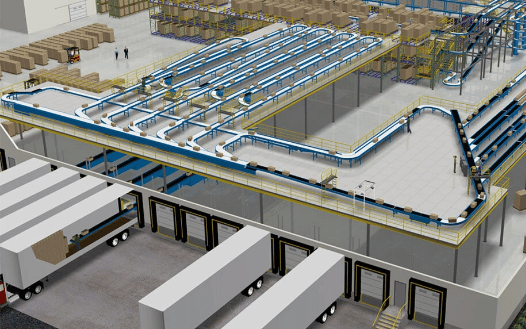

Advanced Intralogistics provides the complete installation of storage solutions and integrated systems throughout your warehouse, distribution center and loading dock. We understand the importance of having reliable and resilient storage for your inventory and products. Our installation team specializes in the implementation of:

Many of today’s high-tech warehouse solutions require both mechanical and technical expertise for proper installation, repair and maintenance. At Advanced Intralogistics, your critical systems will always be in the hands of experienced technicians and installers who know the ins-and-outs of these complex instruments, as well as how to keep them operating in peak condition for as long as possible.

Automation can help increase the productivity of an existing workforce by as much as 46%.

Learn MoreIntegrated Systems and Warehouse Solutions You Can Depend on.