The Case for Automation

Automation can help increase the productivity of an existing workforce by as much as 46%.

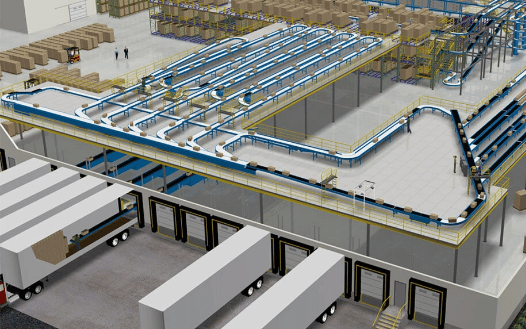

Learn MoreOur customizable, high-tech sortation systems can divert, transfer and sort any type of package, at any point throughout the order fulfillment process.

Sortation Systems come in all varieties and serve their purpose for both inbound and outbound shipping processes.

In environments where delivery times are not vital or don’t involve perishable items, systems can be set up for merchandise to be pre-labeled and unloaded on an inbound door, flow through a conveyance system and divert to an outbound trailer dedicated for a particular store or destination point. This process eliminates the need to palletize, store, replenish and pick inventory.

In environments where there is a lot of labor spent on sortation and palletizing of inbound trucks with multiple SKUs, an inbound sortation system can be configured to send certain SKUs to a destination point where a palletizer can prep the pallet and move from location to location as lines fill up. This process can also be programmed to do the inbound scanning of the shipment, close out the PO, and other automated activities.

Companies that utilize full pallet quantities can use pallet sortation systems to move the pallets from the inbound dock directly to a conveyance system that will bring the pallets to an ASRS system or to a destination for a forklift driver to grab the pallet and put it into a sortation system. This greatly reduces the need for forklift/pallet jacks to transport pallets from point A to point B and the labor needed for these tasks.

Pick Modules: A pick module in a warehouse is a designated area or system that is used to select, gather, and prepare products for shipment. This can include tasks such as locating items on shelves or storage racks, pulling the items from their storage location, and packaging or preparing them for transport. The pick module is typically designed to be efficient and organized, with the goal of minimizing errors and maximizing productivity. This can include the use of automated systems, software, and other tools to streamline the process and ensure accuracy.

Pallet Conveyance Systems: Warehouses that use pallet conveyance systems will have pallets diverted from the storage system (ASRS or traditional rack storage) to an outbound staging location. Some systems will have staging flow racks or lanes to pre-stage the outbound loads for the following day. With the correct WCS and WMS/ERP setup these systems can continue to move pallets through the system during off-hours.

Automation can help increase the productivity of an existing workforce by as much as 46%.

Learn MoreIntegrated Systems and Warehouse Solutions You Can Depend on.