Integration.

Innovation.

Intelligence.

Robotic Arms for Warehouse Management

Make manual product picking a thing of the past. Automated Picking Systems increase efficiency and product flow, eliminating the non-value-added task of tedious hand picking. Allowing you to reallocate your associates to tasks that need a human touch.

Automated Picking Technologies Include:

Advanced Intralogistics solutions consultants are highly experienced, offering expertise in automation technologies and finding the best solutions to meet your fulfillment and inventory needs.

Voice Picking: Workers use a headset and microphone to receive voice-guided instructions for picking items.

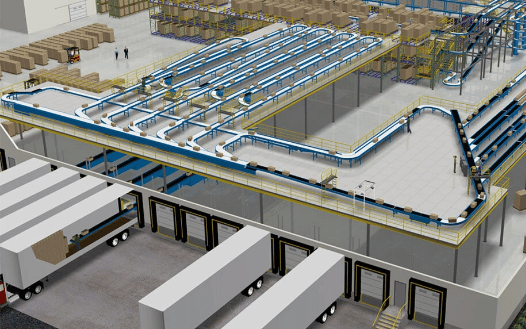

Automated Storage and Retrieval Systems (ASRS): These systems use automated equipment, such as cranes or robots, to retrieve and place items into storage.

Pick-to-Light Systems: This technology involves using lights to indicate where items are located and which items need to be picked.

Automated Warehouse Picking Systems

- Pick-to-Cart Systems: This technology uses a mobile cart equipped with a scanner and display screen to guide workers through the picking process.

- Radio-Frequency Identification (RFID) Systems: RFID technology uses tags and readers to track the location and movement of items in real-time, enabling workers to pick items quickly and accurately.

- Robotic Bin Picking: This technology includes the use of robotic arms to pick and retrieve items from bins or containers. It involves the use of a robot equipped with sensors and vision systems to identify and pick items from a bin or container. The robot uses image processing algorithms to identify the position and orientation of the items and plan its grasping motion.

The Case for Automation

Automation can help increase the productivity of an existing workforce by as much as 46%.